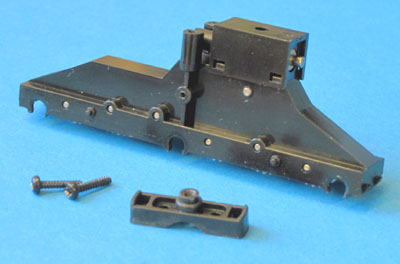

Using a small screwdriver, gently unclip the bogie frame/undertray

moulding from the outer end, then the inner end, of the bogie drive unit. Put the moulding safely to one side for now.

Using a small screwdriver, gently unclip the bogie frame/undertray

moulding from the outer end, then the inner end, of the bogie drive unit. Put the moulding safely to one side for now.Following the manufacturers' recommendations for running-in, ensure that the locomotive is performing smoothly and to your satisfaction generally. Deal with any issues now, especially those covered by warranty or your basic statutory rights as customer, before making any modifications.

Separate the body moulding from the chassis block of the locomotive according to the manufacturer's instructions. Store the body retaining screws safely away.

Select one of the bogies and undo the screw which retains the bogie pivot in the chassis block. Drop the bogie out from the bottom of the block. The cardan shaft joining the motor to the bogie will either come with the bogie or be retained at the motor end. Either way, remove it but note that the ears on each end of the cardan shaft are of subtly different shapes, so record which end is which.

Assign the bogie to one or other of your sets of etched bogie parts, marking the bogie drive, drive shaft and chassis block accordingly.

Similarly remove the other bogie.

Using a small screwdriver, gently unclip the bogie frame/undertray

moulding from the outer end, then the inner end, of the bogie drive unit. Put the moulding safely to one side for now.

Using a small screwdriver, gently unclip the bogie frame/undertray

moulding from the outer end, then the inner end, of the bogie drive unit. Put the moulding safely to one side for now.

Undo the two cross-headed screws retaining the bogie pivot to the tops of the two pivot

towers and remove the pivot. Again put this to one side for later re-use.

Undo the two cross-headed screws retaining the bogie pivot to the tops of the two pivot

towers and remove the pivot. Again put this to one side for later re-use.

Unclip the three wheelsets from the drive unit moulding and put them to one side.

Unclip the three wheelsets from the drive unit moulding and put them to one side.

Undo the cross-headed screws which retain the metal pickup strips on the side of the drive unit moulding. Remove the strips and put them to one side for reuse.

Unclip the worm cover…

Unclip the worm cover…

… and remove the worm with its shaft and bearings. Put them safely to one side.

… and remove the worm with its shaft and bearings. Put them safely to one side.

Rotate the three free idler gears, between the middle and inner axles,

to feel how free running they are,

as you will need to

reproduce this later when reassembling the drive unit.

Rotate the three free idler gears, between the middle and inner axles,

to feel how free running they are,

as you will need to

reproduce this later when reassembling the drive unit.

Gently press out the idler axles. We found that

the axles are a tight fit in one side of the moulding only so, once you have removed the first one and

thereby determined which side that is,

press them out from the tight side and, when the time comes, replace them from the loose side.

Gently press out the idler axles. We found that

the axles are a tight fit in one side of the moulding only so, once you have removed the first one and

thereby determined which side that is,

press them out from the tight side and, when the time comes, replace them from the loose side.

As you push out each axle, remove its gearwheel and record its position in the drive train so that you

can replace it later in the same position.

When removing the idler axles, support the moulding on a hard surface with some kind of slot or hole to receive the axle. We used the blind end of a 1.4mm drill, held in a pin chuck, to push the axles through.

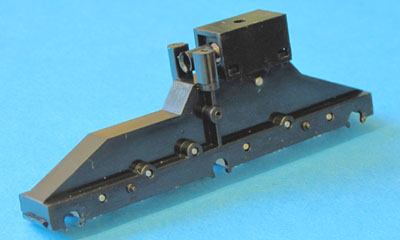

Referring to the 'before' and 'after' illustrations here, and

using your favoured combination of razor saws and craft knives or burrs, cutting discs and

grinders in a mini electric drill, cut down the drive train moulding as follows:

Referring to the 'before' and 'after' illustrations here, and

using your favoured combination of razor saws and craft knives or burrs, cutting discs and

grinders in a mini electric drill, cut down the drive train moulding as follows:

at the ends of the moulding remove the bogie frame retaining clips and then thin down the vertical end

faces of the moulding to about half their original thickness.

at the ends of the moulding remove the bogie frame retaining clips and then thin down the vertical end

faces of the moulding to about half their original thickness.

Make a notch in the end of the worm cover at one end, extending about 3mm from the top and bringing the edge of

the cover flush with the face of the bearing retainer. When refitted, this notch should be facing the drive-

coupling end of the worm shaft.

Make a notch in the end of the worm cover at one end, extending about 3mm from the top and bringing the edge of

the cover flush with the face of the bearing retainer. When refitted, this notch should be facing the drive-

coupling end of the worm shaft.

Exercise some care as, in spite of being somewhat 'soft' and 'soapy', the plastic can crack in a brittle manner if overstressed. Take great care at all stages not to damage the retaining lugs for the main axle bearings.

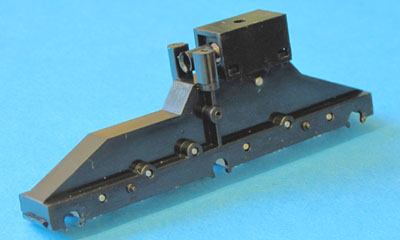

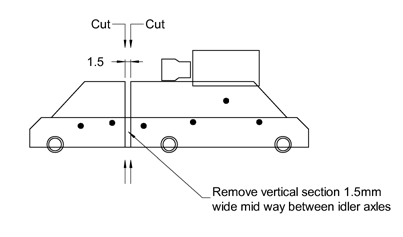

Split the moulding between the inner two axles, by making two vertical cuts as shown here.

Split the moulding between the inner two axles, by making two vertical cuts as shown here.

A razor saw may be used to make these cuts. Take care that the moulding is adequately

supported while cutting - it's helpful to have a solid block of material which just fits between

the sides of the moulding.

A razor saw may be used to make these cuts. Take care that the moulding is adequately

supported while cutting - it's helpful to have a solid block of material which just fits between

the sides of the moulding.

Give the drive unit assembly a thorough wash and degrease to remove all traces of swarf and dust.

Refit the worm gear, the worm shaft and its top cover, with the notched end of the cover towards the drive coupling.

Refit the worm gear, the worm shaft and its top cover, with the notched end of the cover towards the drive coupling.

Refit the three idler gears and axles between the centre and outer axles, adjacent to the worm.

The kit is designed to allow the model to be driven on all six axles, i.e. as a C-C, corresponding to the Co-Co arrangement of the prototype. It is, however, possible to avoid a certain amount of complication by using the 4-wheel parts of the drive as they are and assembling the loco as a B1-1B, in which configuration it will perform perfectly adequately and retain much of its hauling capacity. If you wish to take this option, you can skip the remaining steps in this section.

Remove the Idler Cage etches (6, 7) from the fret. Check that the 1.5mm dia idler

axles, that you removed earlier from the drive unit, are a free fit through the holes in the

plates (Note: one pair of holes is slightly larger than the others).

Remove the Idler Cage etches (6, 7) from the fret. Check that the 1.5mm dia idler

axles, that you removed earlier from the drive unit, are a free fit through the holes in the

plates (Note: one pair of holes is slightly larger than the others).

Smooth the edges of the Idler Cage plates, and remove any remnants of their etch tags.

Fold up the spacers on parts (7),

and check the fit of the plain side (6) in the shaped ends of the spacers of the ribbed side (7).

DO NOT SOLDER THESE COMPONENTS TOGETHER.

Fold up the spacers on parts (7),

and check the fit of the plain side (6) in the shaped ends of the spacers of the ribbed side (7).

DO NOT SOLDER THESE COMPONENTS TOGETHER.

The larger holes in each plate should line up at one end of the idler cage.

Returning now to the three idler gears which have yet to be refitted to the drive unit, thin down

their widths over bosses such that they are a free fit between the two plates of the assembled Idler Cage,

a dimension of about 2.8mm. There may be a small moulding pip on the side of the gear which

should be removed. Ensure that the thinned gears each rotate freely on the idler axles.

Returning now to the three idler gears which have yet to be refitted to the drive unit, thin down

their widths over bosses such that they are a free fit between the two plates of the assembled Idler Cage,

a dimension of about 2.8mm. There may be a small moulding pip on the side of the gear which

should be removed. Ensure that the thinned gears each rotate freely on the idler axles.

The bosses of the plastic gears can be thinned by filing them down. To hold the gear while working it,

clamp one of the idler axles into a collet pin chuck with about 2.7mm projecting. The gear can then be placed

over the axle and worked with the file while holding the pin chuck in the other hand.

The bosses of the plastic gears can be thinned by filing them down. To hold the gear while working it,

clamp one of the idler axles into a collet pin chuck with about 2.7mm projecting. The gear can then be placed

over the axle and worked with the file while holding the pin chuck in the other hand.

The filing operation

will leave 'fuzzy clods' of deconstituted plastic around both the outside edges of the bosses and the axle holes. It is

essential that this waste is removed, using a sharp scalpel blade, as the smallest amount will cause the

gears to run tight on the axles or bind against the transmission plates. Use the scalpel to put the

tiniest of bevels around the circumference of the axle holes and outer edge of the bosses.

Finish cleaning with a wash

of methylated spirits scrubbed by an old toothbrush. Do not be tempted to relieve

the axle holes with a broach or reamer - any tightness will be down to dust, or swarf, lingering in the axle

holes.

Place the ribbed side of the Idler Cage (7) on the bench and locate the central and one of the smaller idler

gears over the two smaller holes in the side of the Cage.

Place the ribbed side of the Idler Cage (7) on the bench and locate the central and one of the smaller idler

gears over the two smaller holes in the side of the Cage.

Clip the plain side of the Idler Cage (6) into place over the gears.

Slide the Idler Cage assembly into the

smaller part of the drive train moulding (it can go in either way up, but the larger pair of holes should

be to the outside), lining up its central hole with the

corresponding hole in the moulding.

Slide the Idler Cage assembly into the

smaller part of the drive train moulding (it can go in either way up, but the larger pair of holes should

be to the outside), lining up its central hole with the

corresponding hole in the moulding.

Press an idler axle into the hole to retain the gear and Idler Cage.

Similarly fit one of the other idler axles in the remaining idler axle position. Check

that the gears rotate freely.

Now slide the exposed end of the Idler Cage assembly into the cut end of the

larger part of the drive train moulding. Slide the remaining idler gear between the plates, line

it up with the holes in the plates, line up the holes in the plates with the holes in the

moulding, and insert the idler axle to retain the axle and plates in position. Check for freedom

of rotation, about the idler axle, between the two parts of the drive train moulding: it should be sufficient for the inner

axle to move up and down about 1mm with respect to an imaginary line joining the centres of the other

two axles. It will probably be much more than this, but if there is a problem just file back the cut

edges of the moulding where they come close.

Now slide the exposed end of the Idler Cage assembly into the cut end of the

larger part of the drive train moulding. Slide the remaining idler gear between the plates, line

it up with the holes in the plates, line up the holes in the plates with the holes in the

moulding, and insert the idler axle to retain the axle and plates in position. Check for freedom

of rotation, about the idler axle, between the two parts of the drive train moulding: it should be sufficient for the inner

axle to move up and down about 1mm with respect to an imaginary line joining the centres of the other

two axles. It will probably be much more than this, but if there is a problem just file back the cut

edges of the moulding where they come close.

Check that the three idler gears rotate freely together as they did before disassembly. If any tightness is present, strip down the gears and ensure that they are clean and free from any kind of swarf or dust residues.

That concludes the modifications to the bogie drive units.