Remove one of the bogies from the chassis block.

Remove one of the bogies from the chassis block.

Following the manufacturers' recommendations for running-in, ensure that the locomotive is performing smoothly and to your satisfaction generally. Deal with any issues now, especially those covered by warranty or your basic statutory rights as customer, before making any modifications.

Separate the body moulding from the chassis block of the locomotive according to the manufacturer's instructions.

Gently slide four cocktail sticks between the body and chassis block, one to the side of each body retaining clip, just far enough to hold the clips clear of the chassis block so that the body may be slipped easily off the block.

Make a note of the identification of the sockets on the circuit board to which the two wire power feeds from each bogie are connected. Note also to which side of each bogie the wires go. Unplug the power feeds from the circuit board.

Remove one of the bogies from the chassis block.

Remove one of the bogies from the chassis block.

To dismantle the Heljan bogie retaining assembly, unclip the top cover of the

drive train as shown. This will allow the two halves of the drive unit to be separated slightly,

allowing the worm gear and bearings to move a little, which in turn allows the bottom of the

circular part of the 'yoke' to be unclipped from the drive unit.

To dismantle the Heljan bogie retaining assembly, unclip the top cover of the

drive train as shown. This will allow the two halves of the drive unit to be separated slightly,

allowing the worm gear and bearings to move a little, which in turn allows the bottom of the

circular part of the 'yoke' to be unclipped from the drive unit.

Remove the plastic yoke.

Remove the plastic yoke.

Strong finger pressure, to lift the edge of the moulded ring over the edges of the chassis block, will allow the yoke to be slid sideways as shown, at which point one end of the moulding becomes free of the block. The moulding is then easily removed.

Assign the bogie to one or other of your sets of etched bogie parts, marking the bogie drive, drive shaft and chassis block accordingly.

Similarly remove the other bogie.

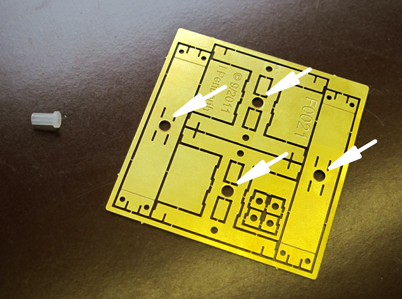

Take the etches for the pivot frames (Fret F002). The pivot holes are etched

to nominal 3/32" diameter. To use the pivot components provided in the kit, open out

the four pivot holes (arrowed) to give a free fit for the 3mm diameter insulators.

Take the etches for the pivot frames (Fret F002). The pivot holes are etched

to nominal 3/32" diameter. To use the pivot components provided in the kit, open out

the four pivot holes (arrowed) to give a free fit for the 3mm diameter insulators.

Open out the holes carefully with tapered broaches to maintain centres.

Remove the pivot frame components from the fret and fold as shown; the photo shows half the components

with first folds made, the other half with all folds made.

Remove the pivot frame components from the fret and fold as shown; the photo shows half the components

with first folds made, the other half with all folds made.

Assemble and solder up the pivot frame components. Test fit the nylon insulators through the pivot

holes.

Assemble and solder up the pivot frame components. Test fit the nylon insulators through the pivot

holes.

Use the tapered broaches again; it will probably be necessary to remove some material from the inside vertical faces of the pivot stiffener to create a free fit for the insulator.

Test fit the pivot frame assemblies in place in the chassis block, lined up with the holes which

retained the plastic yokes. It may be necessary to file the

outside faces of the frames a little to fit the tapering casting.

Test fit the pivot frame assemblies in place in the chassis block, lined up with the holes which

retained the plastic yokes. It may be necessary to file the

outside faces of the frames a little to fit the tapering casting.

Secure the pivot frames in place. The frames may be secured by lengths of 3mm plastic rod

inserted through the holes in the sides of the chassis casting and engaging in the square sockets

in the sides of the frame assemblies. You may need to file flats on the lower faces of the rods to

get them to fit in the sockets. The plastic cylindrical shafts of the original yokes, cut off,

make suitable rods for this purpose if you are prepared to sacrifice them.

Secure the pivot frames in place. The frames may be secured by lengths of 3mm plastic rod

inserted through the holes in the sides of the chassis casting and engaging in the square sockets

in the sides of the frame assemblies. You may need to file flats on the lower faces of the rods to

get them to fit in the sockets. The plastic cylindrical shafts of the original yokes, cut off,

make suitable rods for this purpose if you are prepared to sacrifice them.

Alternatively holes are provided in the pivot frames to allow drilled and tapped screw fixings

to be made.