Now we can fit the Heljan gears to the new axles and assemble the wheelsets.

Do the following for each axle.

Now we can fit the Heljan gears to the new axles and assemble the wheelsets.

Do the following for each axle.Four 2mm diameter plain-ended axles are required. Pin-pointed ends should be

removed. If you are using ready-assembled wheelsets it will be necessary to

remove at least one of the wheels from the axle.

For discussion on the possible choices of wheels, see the

Wheels and Axles section of the

Technical Description page on the website.

Clip the top covers on to the drive units. This will prevent the units from falling apart while you then spring off the bottom covers to access the wheelsets.

Remove the four OO wheelsets from the drive units, dismantle them and recover the four final drive gears.

We use one of the axles to check for lateral play. It is important that there is sufficient play, for the subsequent free-running of the loco: a little loose is better than a little tight.

Take one of the axles, slide on its bearing carriers and fit its wheels to the correct back-to-back measurement.

Test fit the axle in the bogie subframe to determine the amount of lateral play.

There should be just a little; enough to allow the wheelset to tilt such that the

wheel on one side is raised about 1mm with respect to that on the other, and to allow the wheels

to spin freely.

If there is too much play, strip down the wheelset and insert 2mm washers (half-

and full-thickness washers are provided on the main fret), between the axle bearings and the wheels,

as required.

If there is insufficient lateral play, even with no washers

fitted, then strip down the wheelset and reduce the inner width of the wheel bosses accordingly.

Record the washer configuration you arrived at and dismantle the wheelset. If you had to reduce the inner wheel bosses, repeat the operation on the remaining wheels.

Now we can fit the Heljan gears to the new axles and assemble the wheelsets.

Do the following for each axle.

Now we can fit the Heljan gears to the new axles and assemble the wheelsets.

Do the following for each axle.

If you have one wheel already fitted to the axle, slide on the required number

of washers adjacent to that wheel, then the bearing carrier (ears facing the wheel).

If you are using the

'American' pickup system make sure that the insulated wheel is adjacent to the carrier for the

insulated side of the bogie.

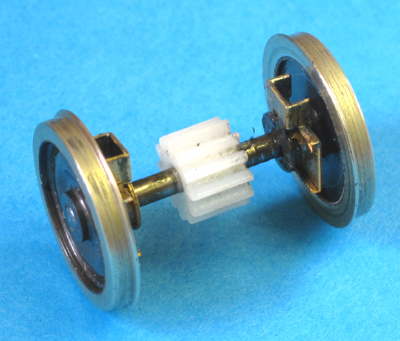

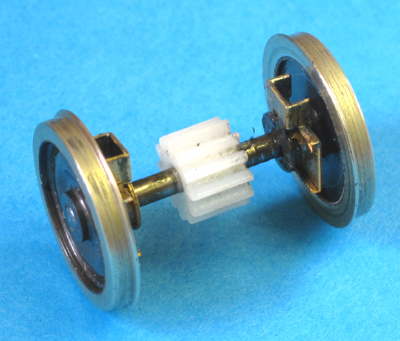

Slide one of the Heljan final drive gears into position centrally on the axle. The gear should be a tight fit on to the axle, sufficient to transmit drive forces without slipping. Take care to ensure that the gear is centrally located on the axle.

Slide the bearing carriers, then any washers required, on to the axle.

Fit the wheels to the axle to the correct back-to-back measurement.

Test fit the axle in its slot to confirm that there is sufficient lateral play.

Lubricate the bearings with a light machine oil and ensure that the oil is taken in to all the axle-bearing interfaces.

That completes the assembly of the wheelsets.