Remove the coupling from the bogie frame.

Remove the coupling from the bogie frame.

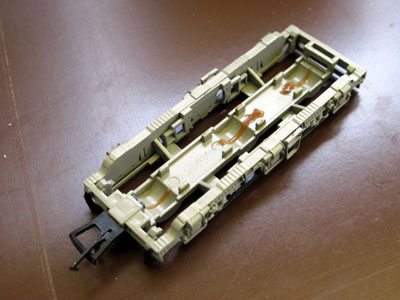

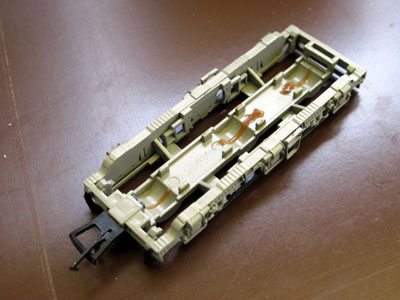

In this section we remove unwanted material from the Bachmann moulded bogie frame and attach the remaining cosmetic detail to the etched bogie subframe.

Remove the coupling from the bogie frame.

Remove the coupling from the bogie frame.

Cut the brake pull rods at the shoe end using a sharp scalpel; support the shoe itself while you do this.

Break the adhesive bond at the inner end of the pull rod and remove the rod.

Cut the brake pull rods at the shoe end using a sharp scalpel; support the shoe itself while you do this.

Break the adhesive bond at the inner end of the pull rod and remove the rod.

Remove the undertray. Be careful not to overstress the moulded end stretchers. Start by cutting through

the coupler moulding, as close to the line of the backs of the stretchers as you can...

Remove the undertray. Be careful not to overstress the moulded end stretchers. Start by cutting through

the coupler moulding, as close to the line of the backs of the stretchers as you can...

...then cut the intermediate stretchers flush with the back of the central brake/spring detail moulding...

...then cut the intermediate stretchers flush with the back of the central brake/spring detail moulding...

... and finally cut the inner end of the undertray from the backs of the inner stretchers. Clean up

the cuts at the inner and coupler ends such that the backs of the stretchers present a single flat surface

across the width of the bogie.

... and finally cut the inner end of the undertray from the backs of the inner stretchers. Clean up

the cuts at the inner and coupler ends such that the backs of the stretchers present a single flat surface

across the width of the bogie.

Clean up the stubs of the intermediate stretchers, and file their vertical faces to fit between the

outriggers of the etched subframe assembly.

Clean up the stubs of the intermediate stretchers, and file their vertical faces to fit between the

outriggers of the etched subframe assembly.

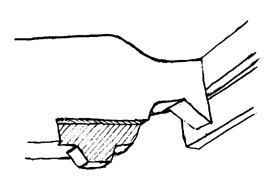

Cut the central brake detail from the secondary spring mouldings as shown. Ensure

the components are well supported when making the cuts. Cut about a further 1mm from the ribs which

linked to the secondary springs. Remove the moulding which links the brake shoes, cutting as shown

so that no part of the blocky moulding at the top of the shoe will interfere with installation of

the central wheelset.

Cut the central brake detail from the secondary spring mouldings as shown. Ensure

the components are well supported when making the cuts. Cut about a further 1mm from the ribs which

linked to the secondary springs. Remove the moulding which links the brake shoes, cutting as shown

so that no part of the blocky moulding at the top of the shoe will interfere with installation of

the central wheelset.

Remove the end brake shoes from the bogie and remove material as shown so that they will

sit a little further away from the outer axles.

Remove the end brake shoes from the bogie and remove material as shown so that they will

sit a little further away from the outer axles.

Cut a rebate on the inside of the moulding at the base of each outer axle detail as shown. This is to take

the end of the pull rod detail and should be 0.4-0.5mm deep.

Cut a rebate on the inside of the moulding at the base of each outer axle detail as shown. This is to take

the end of the pull rod detail and should be 0.4-0.5mm deep.

Glue the central brake shoes in place as shown, spaced such that a wheelset can just drop in between them

from the top.

Glue the central brake shoes in place as shown, spaced such that a wheelset can just drop in between them

from the top.

'Plastic Weld' is a solvent adhesive which works well for re-attaching these components.

Refit the outer brake shoes to the end stretchers, spacing them as far as they will go into the corners

of the moulding, the top detail then dictating a small clearance between the shoe and the inside of the

side moulding.

Refit the outer brake shoes to the end stretchers, spacing them as far as they will go into the corners

of the moulding, the top detail then dictating a small clearance between the shoe and the inside of the

side moulding.

Using a quick-set epoxy resin, glue the pull rod detail etches in place between the lower ends of the outer shoe details and the rebates in the inside of the sideframe moulding.

If you wish to solder a coupling to the bogie subframe, it is as well to do it now before attaching the plastic outer frames. Note that if you are using 'American' style pickup it might be advisable instead to fit an insulating coupling mount.

Again using quick-set epoxy, fix the moulded bogie frame to the end stretchers and outriggers of the

etched bogie subframe. Note that the production version of the end stretchers is slightly different

to that shown here.

Again using quick-set epoxy, fix the moulded bogie frame to the end stretchers and outriggers of the

etched bogie subframe. Note that the production version of the end stretchers is slightly different

to that shown here.